Engineering the Future of Your Production Line

We design and build custom automation machinery that solves your unique challenges and drives your business forward.

Discuss Your ProjectOUR CLIENTS

Our Core Specialties

We excel in creating tailored solutions across various automation needs.

Robotic Integration

Seamlessly integrating state-of-the-art robotics to enhance speed, precision, and safety in your operations.

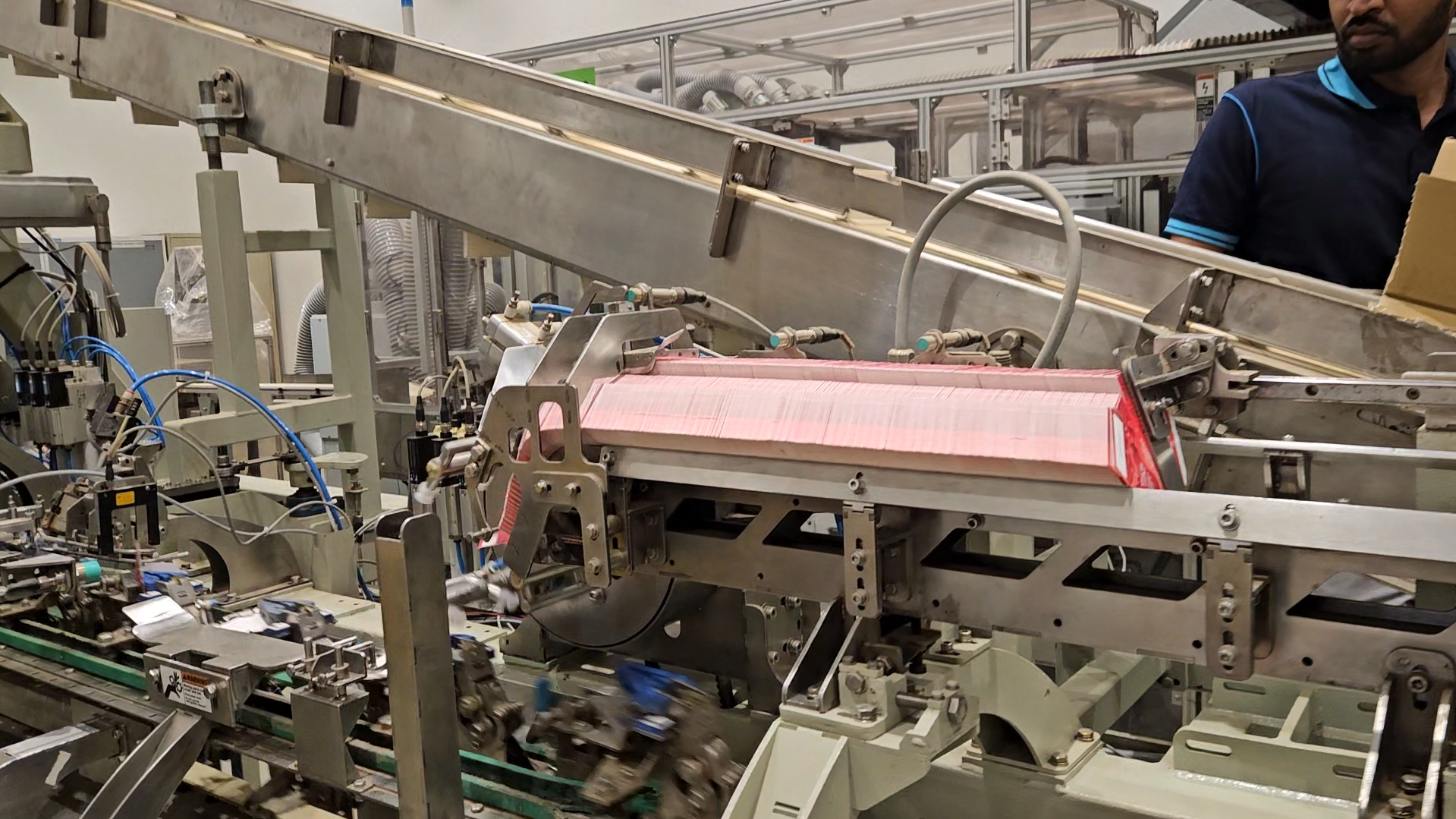

Custom Automatic Machinery

Designing and building complete automatic machines from the ground up, optimized for your specific product and workflow.

Automated Quality Control

Implementing advanced vision systems and sensors to ensure every product meets the highest quality standards, automatically.

Why Partner with NST Automation?

We're more than just machine builders; we're your dedicated automation partner.

- Turnkey Solutions: From initial concept to final installation and support, we handle everything.

- Deep Expertise: Our team brings decades of combined experience in mechanical and electrical engineering.

- Collaborative Process: We work closely with you at every stage to ensure the final product exceeds expectations.

- Built to Last: We use only high-grade materials and components, ensuring reliability and a long service life.

VISIT OUR EVER-GROWING PORTFOLIO

Visit Here >Ready to Automate Your Process?

Let's talk about your goals and how a custom solution from NST can get you there. Reach out for a no-obligation consultation.

Get Your Free Consultation